There were roughly a quarter-million Rhodes produced during the CBS and Fender production years. We like to think that most of them are still around and it's safe to assume that most of them are under-serviced. So if you've just bought a Rhodes or are finally getting around restoring that dusty thing in the basement here are few places to start.

Grommets: These degrade regardless of use. The reason is that, unlike the hammer tips, they are a rubber product and not neoprene. Also they are under constant stress from both the weight of the tone bars and the pressure from the springs underneath. Many rhodes are also poorly serviced over the years, one of the most common examples being over-tightened tone bars. The bars should be spaced about 3/8" from the plywood. However because they're the easiest part to access and adjust many people use these to address other problems such as weakening bridle straps or poorly adjusted damper felts.

The original grommets were already prone to being squished out (which causes them to become dry and brittle even quicker) but over-tightening really destroys the grommets quickly. It rarely effects the strength/resiliency of the springs but this can also be something to look out for.

Worn grommets, particularly original grommets can also lead to a host of other minor problems beyond directly affecting the sound. Most importantly they can throw off the alignment of the tine in relation to the hammer tip, the felt and the magnet/pickup. For this reason and the tonal difference we illustrate in the following videos we recommend replacing the tone bar grommets before any other restoration is done.

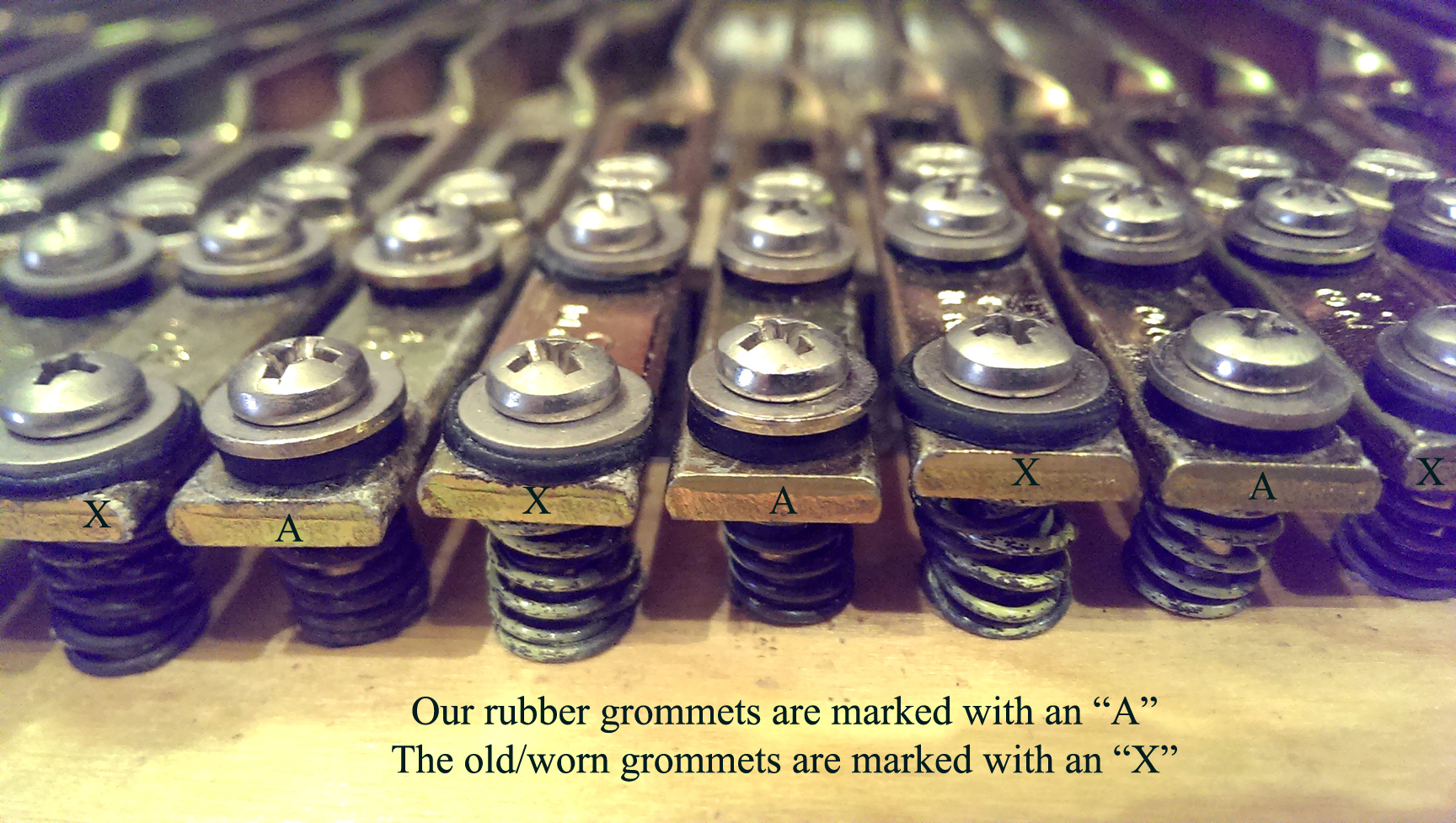

Above are some old original grommets pulled off a 1978 Rhodes. Some of these actually crumbled when we removed them. You can see the "mushrooming" from the pressure of the springs and weight of the tone bars and also the uneven wear from side to side which will cause misalignment and make adjustment difficult. Our improved grommet is pictured also for comparison.

Below: as an experiment/demonstration we replaced every other tonebar with new grommets to show a side by side comparison of old versus new.

Next Up: Bridle Straps

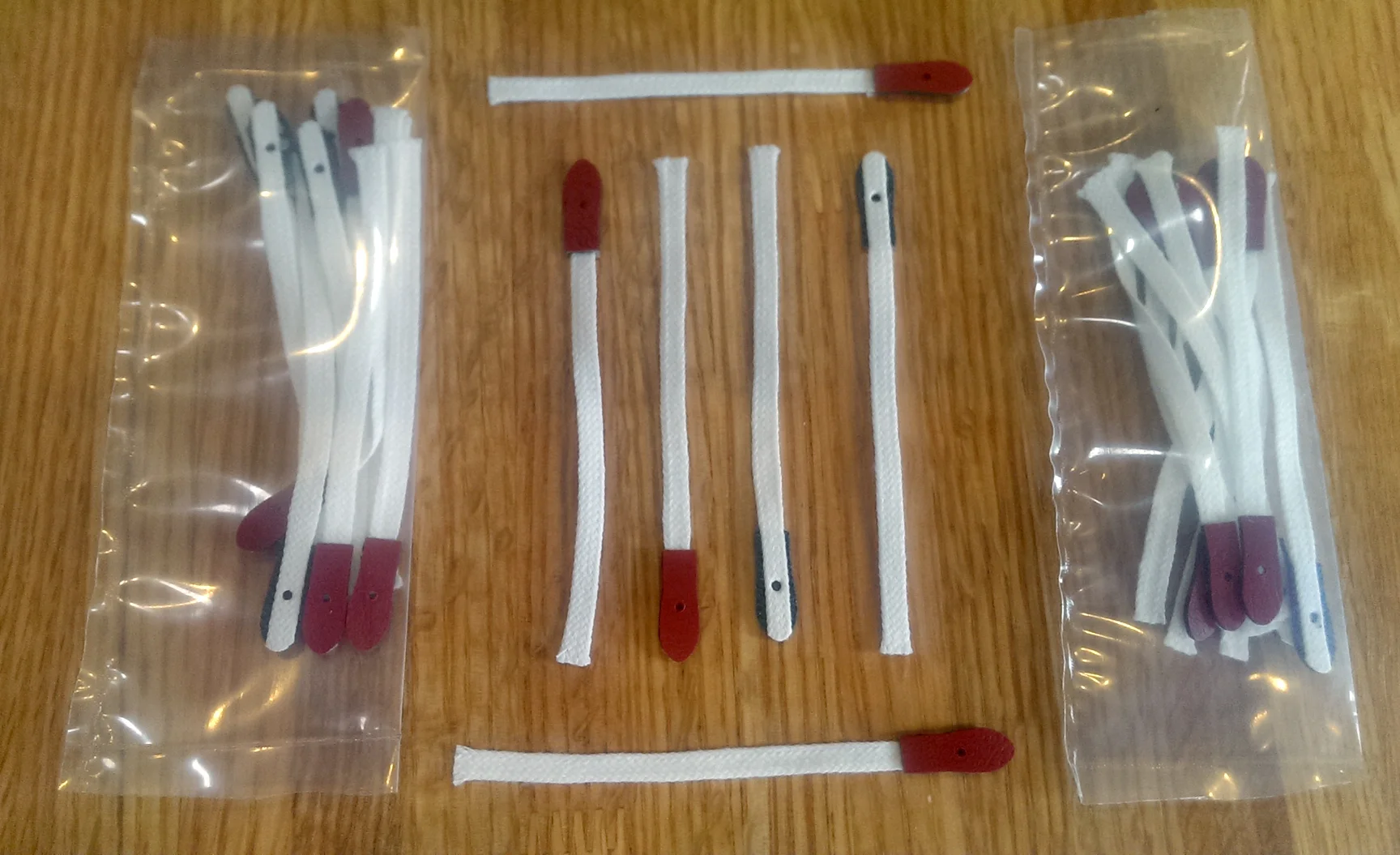

Bridle straps are the key link between the hammer and the spring damper. They are simple cloth cords with reinforced tips. Used normally in the upright piano action they are put in a different situation in the fender rhodes. Most importantly they are under a constant and variable amount of stress whereas in upright pianos the bridle strap is normally slack except when involved in the key/hammer return. Because of this we recommend a "heavy duty" bridle strap with a very strong reinforced tip. But no matter what, the bridle strap is under an unusual amount of stress in the Rhodes design.

*Quick note: replacing bridle straps is not hard....but it is tedious. We usually use a new clean razor blade to first work the glue away then slowly work the braid out of the hammer slot. The most important thing is that you take your time to avoid breaking any of the clips. The blunt edge of the utility knife blade can be used to gently push/wiggle the new strap into the hammer clip.

So back to this unusual stress. The damper spring is constantly pulling on the bridle strap so even in barely used instruments the bridle straps are often degraded. This can be something subtle like a a slight stretching or tearing around the hole all the way to being full ripped which totally disables the release of the felt damper as the hammer comes up. We often tell people that replacing the bridle straps is by far the best "bang for the buck" as they're a pretty inexpensive part and the feel of the action is hugely dependent on them. Properly tensioned and intact bridle straps enable proper damper let-off and they also assist gravity with key return - making the keys feel "faster".

*Another installation note: stretch your bridle straps! Simply hold the tip and squeeze the cord while you pull away. Doing this will help give you a more consistent tension during installation and avoid any straps becoming slack as time passes.

Number Three: the Damper Felts

Some people think hammer tips should be on this list - but really they only degrade with wear. Felt dampers on the other hand (and in some cases foam dampers) do succumb to the ravages of time. And sometimes bugs. For that matter any of the felt on your Rhodes - like the key rail punchings or the name rail felt can become downright useless with little more than aging. (Moisture and temperature also play a big role.) But damper felts are often the first felt product to need swapping out.

The Rhodes has had a considerable amount of variation concerning felt dampers over the years. For the most part Fender used a square or rectangular felt damper of varying size but as I mentioned earlier they also experimented with notched foam, notched felt and angled pieces of dampening felt in order to affect the damper travel and maximize the release. The most substantial change coming with the Mark V where the hammer rail was rearranged and the placement of the damper springs changed.

Whichever style of felt they used in the factory most replacement damper felts will fit and function normally. There are some advantages to both the square and notched replacements. The square ones ensure a clean let-off and require less adjustment or fine tuning of the action. While notched felts dampen better, keep the tine centered and minimize vibration from other sources (playing other keys, sitting next to a drummer etc..)

Final Note: For a lot of people dead keys or sour notes are addressed one by one as they arise. But ultimately while some parts of the Rhodes should last a lifetime - others were never meant to last longer than a decade or two at most. If and when you're ready to start refurbishing your Rhodes look at these parts first to make the restoration go easier. Focusing on these parts first will make adjusting and doing further restoration go much more smoothly and help in identifying issues in other areas.